WS Full CNC SERIES - Sir Meccanica

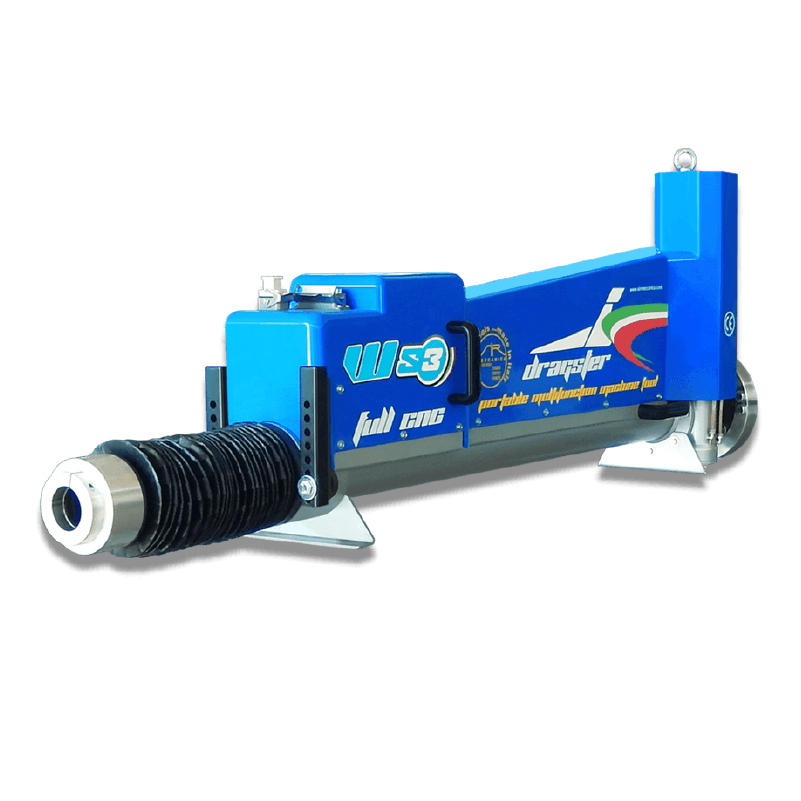

WS Full CNC SERIES

Die Serie Ws Full CNC umfasst sechs Modelle, die alle Vorteile der Ws-Serie besitzen, erweitert durch einen Computer Numerical Control (CNC)-Kopf, der extrem präzise Bearbeitungen ermöglicht, wie zum Beispiel:

- KURVENLINIGE PROFILE

- KONISCHE BEARBEITUNGEN

- FASESCHLEIFEN UND -ANFASUNGEN JEGLICHER ART

- ALLE GEWINDEARTEN

- PLANFRÄSEN VON EINFACHEN UND KOMPLEXEN PROFILFLÄCHEN

- JEGLICHE ART VON NUTEN

- PHONOGRAFISCHE RILLEN

Seriendetails

Die Werkzeugmaschinen von Sir Meccanica sind äußerst vielseitig und finden in allen Industriezweigen Anwendung. Sie können für die Reparatur und Instandhaltung beliebiger Rohrkörper eingesetzt werden und sind in jeder Position funktionsfähig.

Dank ihrer Tragbarkeit führen unsere Werkzeugmaschinen die Bearbeitung direkt vor Ort durch, wodurch Demontagen, Transportkosten und Stillstandszeiten der zu reparierenden Anlagen vermieden werden.

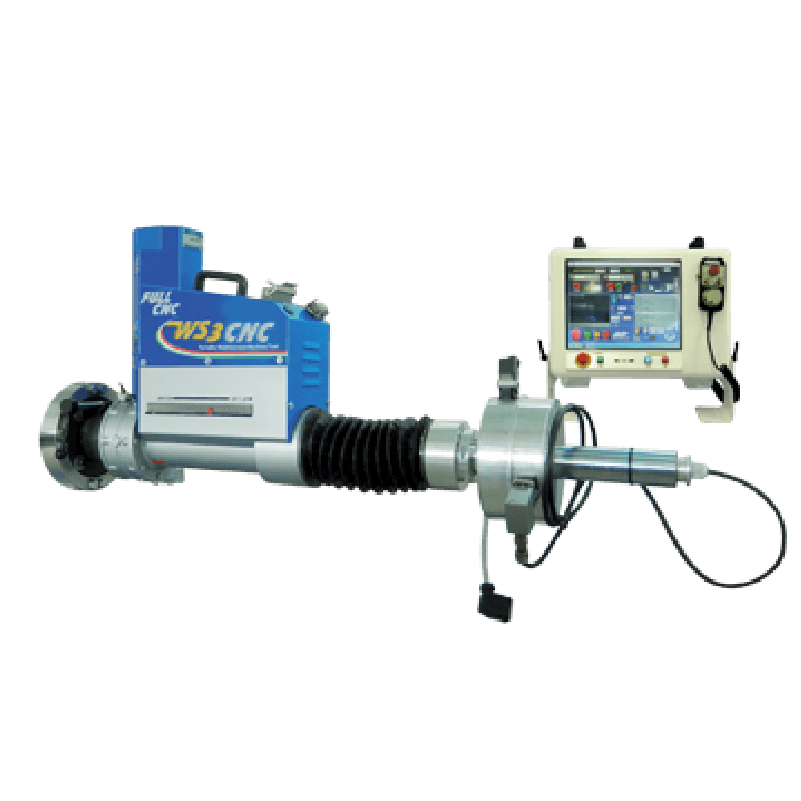

Die Kosten dieser Werkzeugmaschinen können in kurzer Zeit amortisiert werden. Sie sind leicht zu bedienen und erfordern kein hochspezialisiertes Fachpersonal. Sobald die Maschine auf dem zu reparierenden Bauteil positioniert ist, arbeitet sie halbautomatisch und reduziert die Bearbeitungszeit um 95 %.

Die Maschine ist mit einem elektronischen Bedienpult ausgestattet, das über ein Touchscreen-Display verfügt. Die CNC-Schnittstelle ist einfach und intuitiv. Neben der Möglichkeit, Programme manuell zu erstellen, können auch Dateien ausgeführt werden, die mit hochentwickelten CAM-Programmen erstellt wurden, ohne dass Befehlszeilen eingegeben werden müssen.

Die drei Modi FILE, JOG und MDI werden vollständig unterstützt und können gleichzeitig genutzt werden.

Die KUPPELBAREN WELLEN MIT KONISCHEM KUPPLUNGSSYSTEM sind das Ergebnis eingehender Forschungsarbeiten von Sir Meccanica.

Das Hauptziel unserer Forschungs- und Entwicklungsarbeit besteht darin, das seit Jahren verfolgte Engagement für präzise Kupplungen und deren Widerstandsfähigkeit gegenüber mechanischen Belastungen kontinuierlich fortzuführen.

Insbesondere haben wir Studien über die Verriegelungsmechanismen von Kegelverbindungen durchgeführt, die zum Zusammenbau von rotierenden und stationären Teilen dienen, die in der Lage sind, hohe Torsionsmomente zu übertragen, oder zum Verbinden von dünnen axialen Komponenten, die in der Länge ausgedehnt sind und großen Torsions- und Biegemomenten standhalten können.

Das patentierte System, das sich perfekt sowohl an minimale als auch an unbegrenzte Bearbeitungslängen anpassen lässt, besteht aus verschiedenen modularen Komponenten unterschiedlicher Größen, die zusammengebaut die erforderliche Dimension erreichen. Tatsächlich macht die Modularität des Systems die Produkte und Technologien von Sir Meccanica noch einzigartiger.

Die Hauptvorteile unserer Wellen sind:

- sofortiges Kuppeln und Entkuppeln für kontinuierliche Montage und Demontage;

- Präzision und Qualität bei der koaxialen Ausrichtung unter allen Belastungsbedingungen;

- hervorragende Kontrolle der Übermaßpassungen zwischen gekuppelten Flächen;

- Verschleiß- und Belastungsbeständigkeit über die Zeit;

- hohe Drehmomentübertragungskapazität;

- erhöhte Sicherheitskoeffizienten;

- Austauschbarkeit.