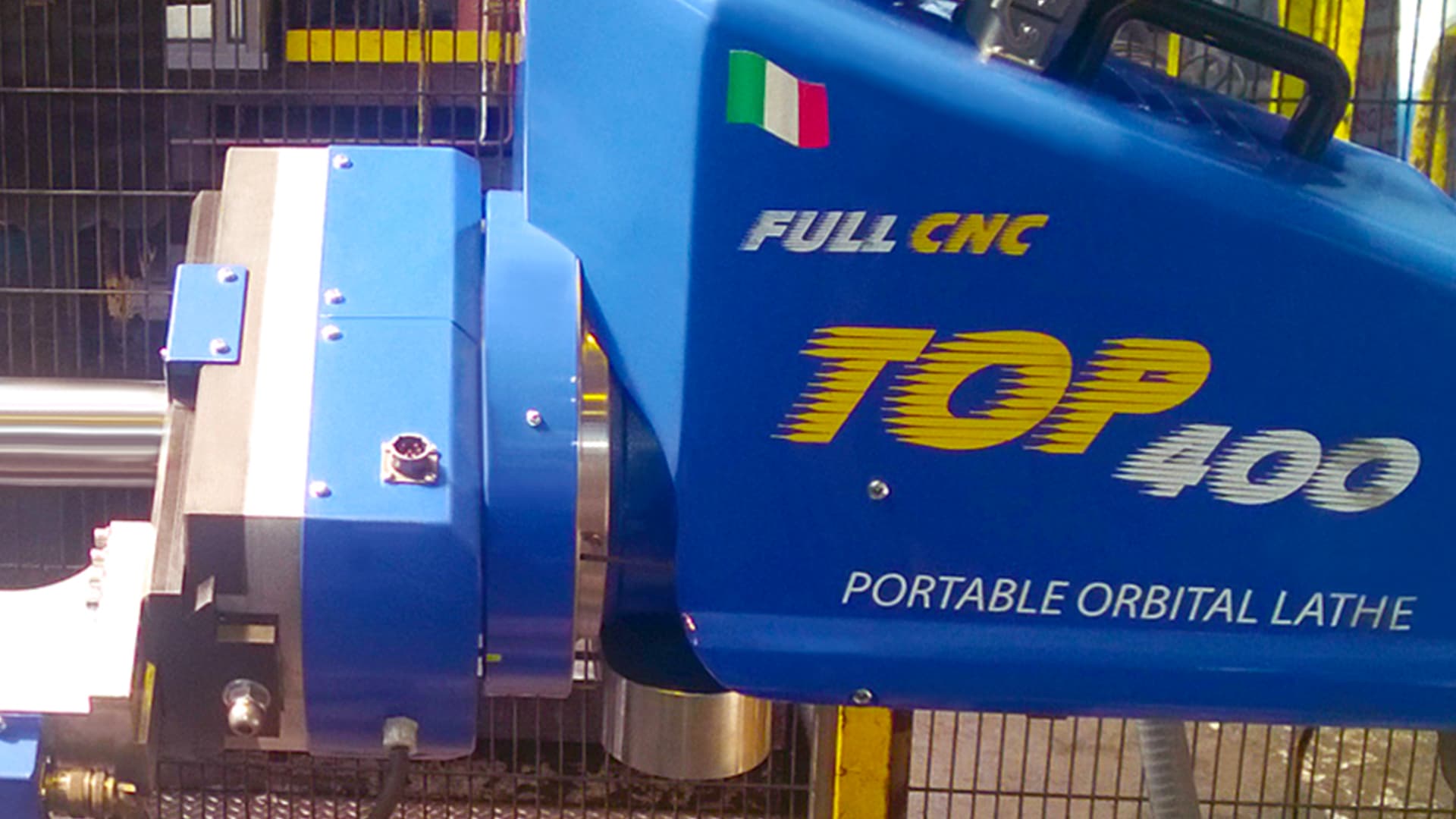

TOP 400 - Sir Meccanica

TOP 400

Описание и приложения.

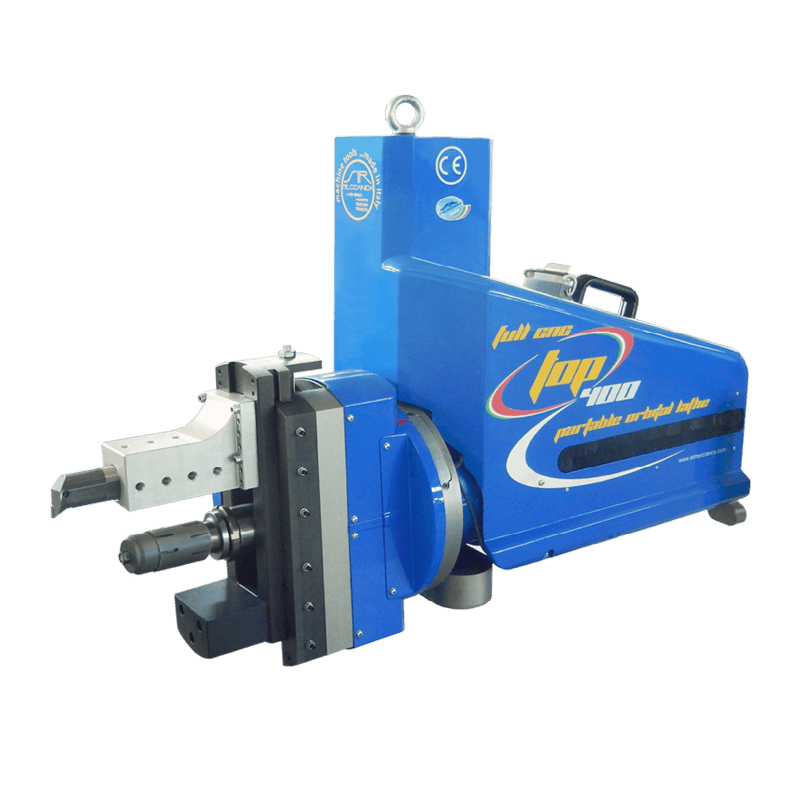

TOP 400 — это уникальный, запатентованный портативный многофункциональный токарный станок с числовым программным управлением (ЧПУ), предназначенный для обработки внутренних и наружных поверхностей, а также торцов неподвижных, не вращающихся трубчатых деталей, которые невозможно обработать на традиционных станках.

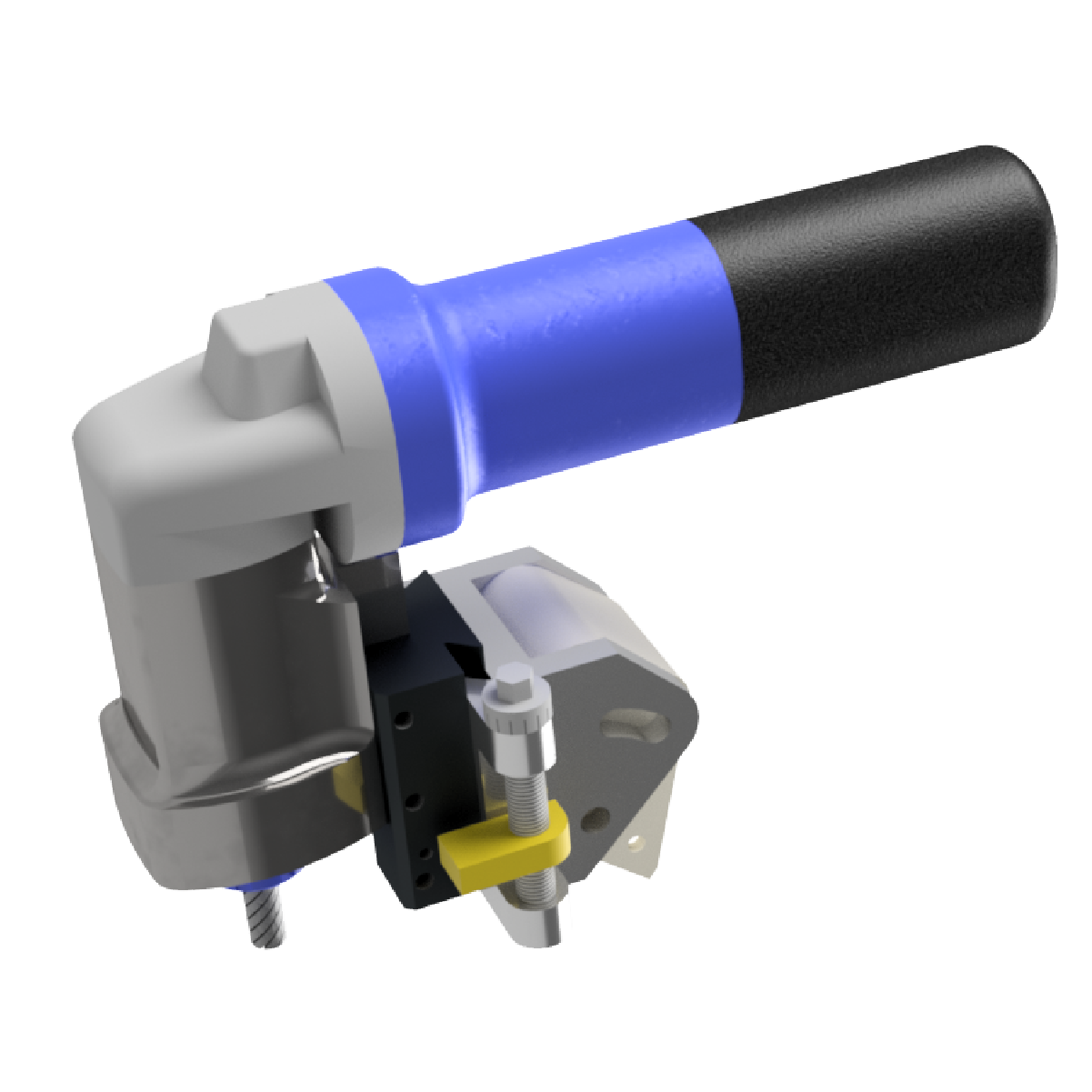

Подходит для самых разнообразных, сложных и высокоточных токарных операций:

• ЛЮБЫЕ ГЕОМЕТРИЧЕСКИЕ ПРОФИЛИ;

• СТАНДАРТНАЯ И КОНИЧЕСКАЯ РЕЗЬБА;

• ПРОСТАЯ И ФИГУРНАЯ ТОРЦОВКА;

• МНОГОУРОВНЕВЫЕ ЦИЛИНДРИЧЕСКИЕ КАНАВКИ.

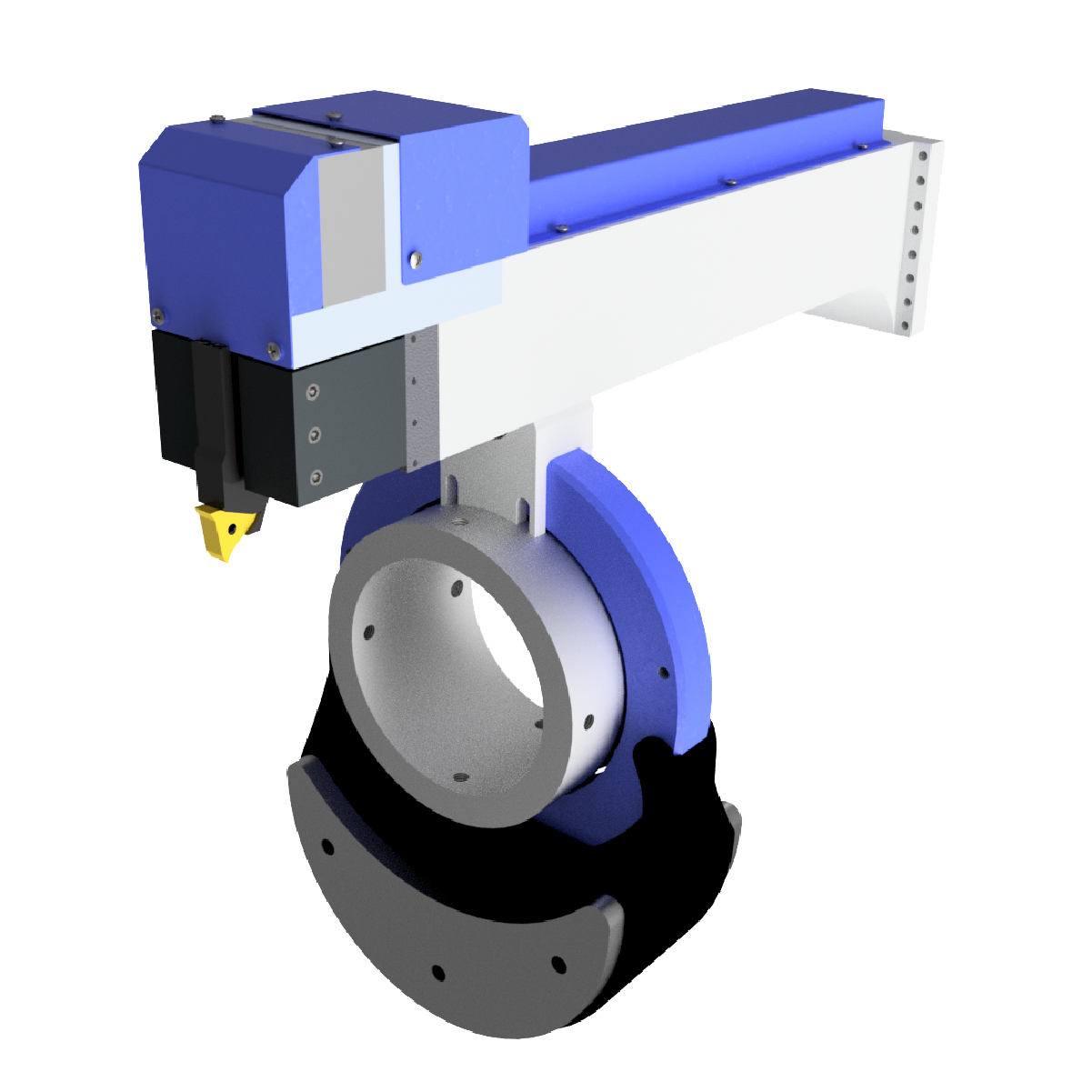

Обрабатываемые диапазоны

Ø 0мм - Ø 400мм (0” – 15.75")

Радиальный ход (ось X)

80мм (3.15”)

Продольный ход (ось Z)

320мм (7.87”)

Информация о продукции

Система Wizard устраняет необходимость программирования на G/M-кодах и значительно упрощает управление благодаря возможности использования графического интерфейса. С помощью Wizard можно изменять скорость любого параметра и получать новый G-код, просто изменяя один из них.

Станки серии TOP могут быть индивидуально изменены. Заказчик может предоставить техническому персоналу все необходимые данные и геометрические характеристики для разработки решений, соответствующих его конкретным требованиям.

ЧПУ-система управления полностью контролирует перемещения осей станка, чтобы переместить инструмент в нужное положение за заданное время. Панель разработана для удовлетворения реальных потребностей операторов токарных станков с ЧПУ. Вот некоторые особенности:

- Используемая CNC-система чрезвычайно простая и практичная. Базовое программирование осуществляется в формате ISO.

- Визуализация 3D-предварительного просмотра траектории инструмента с функцией масштабирования для фокусировки на нужных деталях.

- Простота в использовании: позволяет создавать траектории непосредственно на станке, начиная с чертежа.

- Станком могут управлять даже операторы с минимальным опытом программирования. Стандарт разговорного программирования также позволяет создавать сложные профили.

- Помимо возможности ручного создания программ, можно выполнять файлы, созданные в системах CAM, без необходимости ввода команд вручную.

- Три режима — FILE, JOG и MDI — полностью интегрированы и могут использоваться совместно. Можно открыть файл, просмотреть его, ввести команды в режиме MDI и переключиться в режим JOG без ограничений.

- Набор окон настройки позволяет точно задать обработку и отобразить симуляцию траектории инструмента.

Что это такое?

Мобильные станки с ЧПУ от Sir Meccanica оснащены удалённой системой управления, которая повышает эффективность работы, сокращает время простоя оборудования и обеспечивает своевременную и целенаправленную техническую поддержку, при этом соблюдая конфиденциальность и безопасность данных клиентов.

Удалённое управление — это технологическое решение, ориентированное на клиента, предоставляющее эффективную и безопасную службу поддержки. Удобство удалённого управления в сочетании с возможностями диагностики, обновлений и внедрения новых функций представляет собой значительное дополнительное преимущество, способствующее оптимизации инвестиций в оборудование с ЧПУ и обеспечению максимальной производительности и конкурентоспособности на рынке.

ХАРАКТЕРИСТИКИ СИСТЕМЫ

Система основана на программной платформе, обеспечивающей безопасное двустороннее соединение между станком и нашим сервисным центром; соединение может быть активировано только клиентом с использованием временных учётных данных. Удалённое управление осуществляется через обычное интернет-соединение, а при отсутствии проводного соединения — легко настраивается с помощью USB-адаптера Wi-Fi (клиент обеспечивает стабильное интернет-соединение с достаточной пропускной способностью для корректной работы сервиса). Основные преимущества:

- Продление срока службы оборудования.

- Проактивная техническая поддержка и немедленное решение задач: удалённая диагностика и программная помощь без ожидания, с целью сохранения целостности и эффективности станка.

- Снижение затрат: уменьшаются командировочные расходы технического персонала.

- Простота использования: подключение легко управляется клиентом.

- Прозрачность: клиент может контролировать действия техника во время удалённой сессии.

ОСНОВНЫЕ ФУНКЦИИ

- Продвинутая диагностика неисправностей: анализ рабочих параметров, системных журналов и кодов ошибок в режиме реального времени.

- Удалённый контроль: мониторинг состояния компонентов и датчиков, корректировка параметров — всё это позволяет нашим специалистам быстро определить природу неисправностей или снижения производительности и при необходимости запланировать физическое вмешательство.

- Обновления ПО: прошивки, управляющее программное обеспечение, обновления безопасности и новые функции могут устанавливаться удалённо.

- Расширение функционала: постоянная оптимизация производительности за счёт внедрения макросов, индивидуальных рабочих циклов и новых программных помощников.

Фотогалерея