СЕРИЯ WS - Sir Meccanica

СЕРИЯ WS

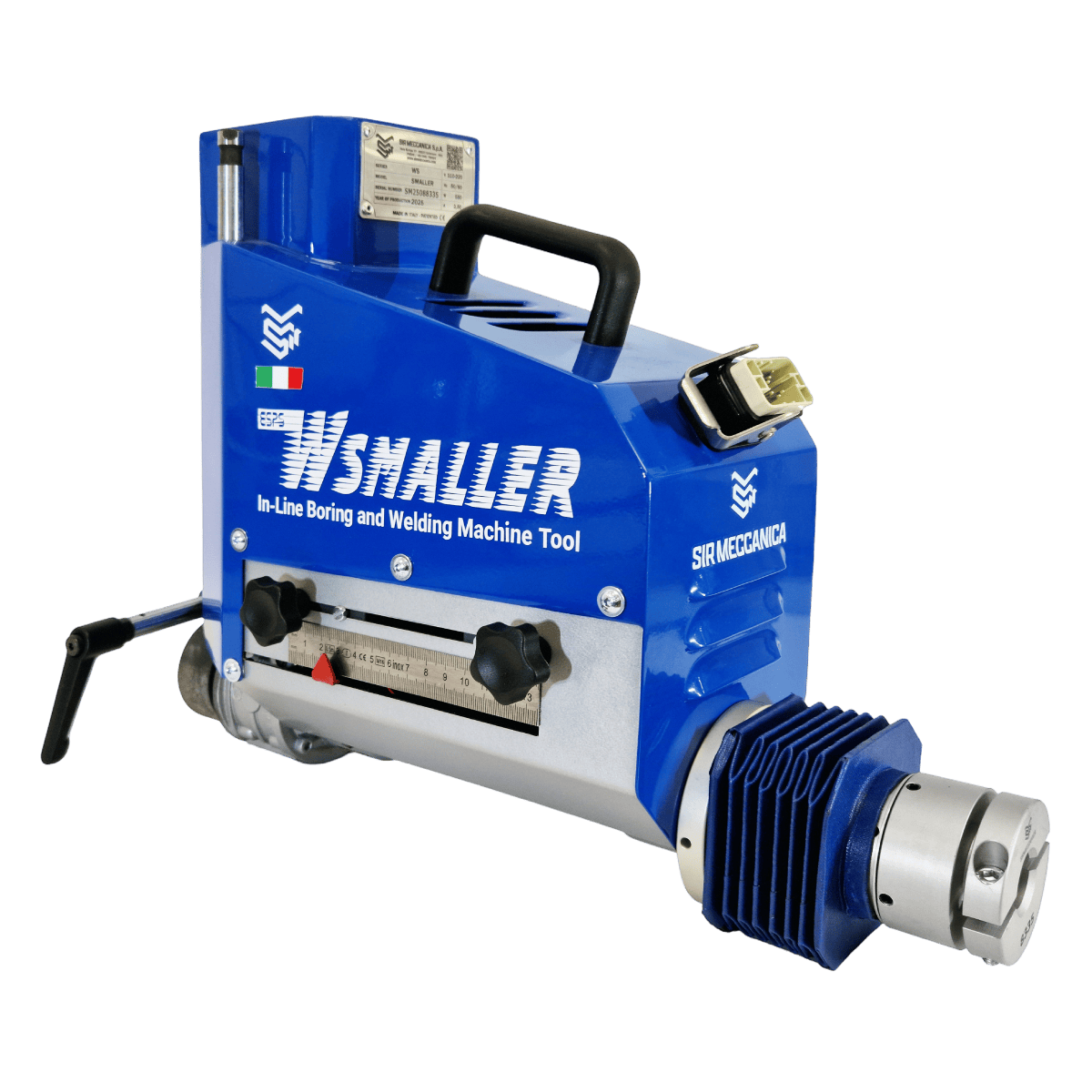

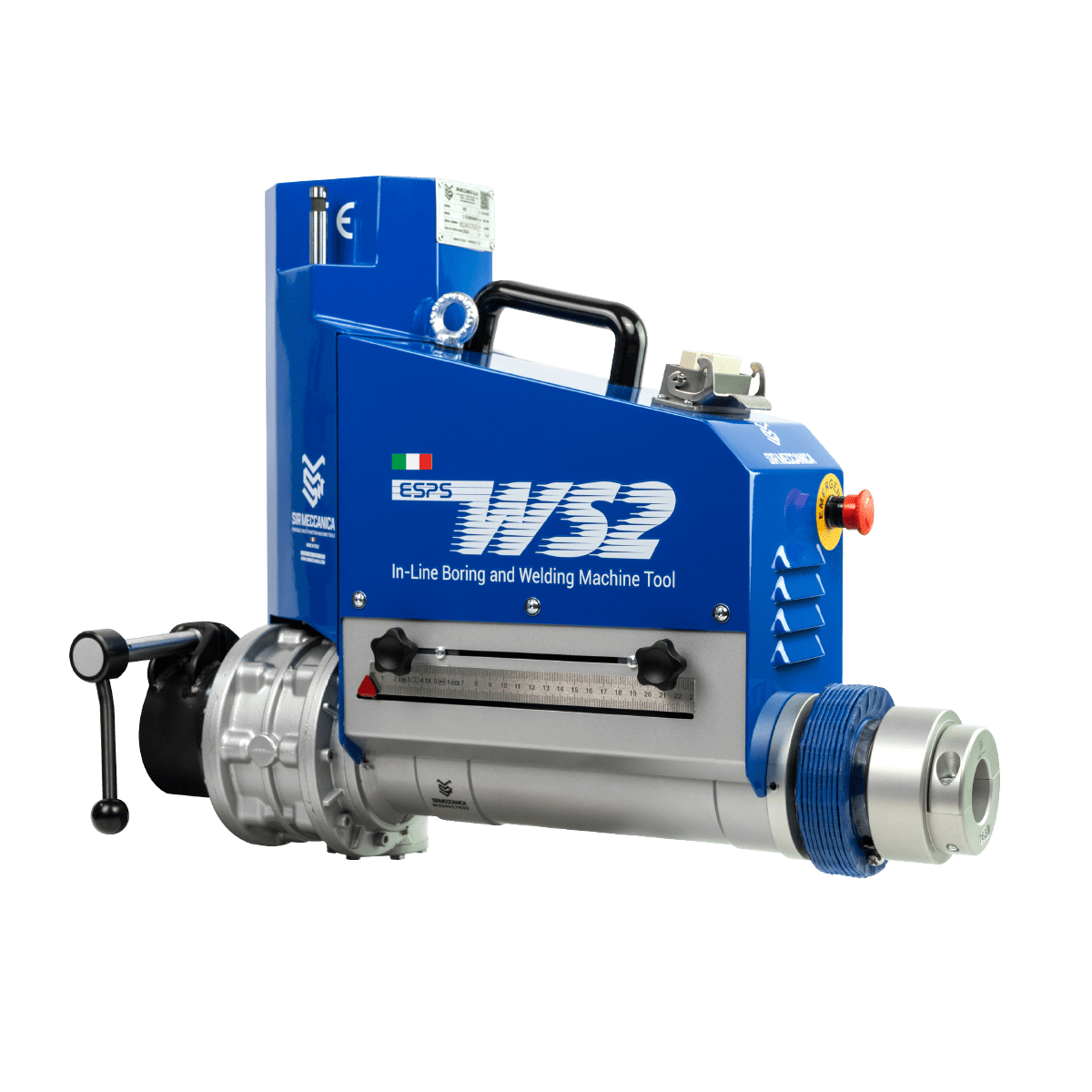

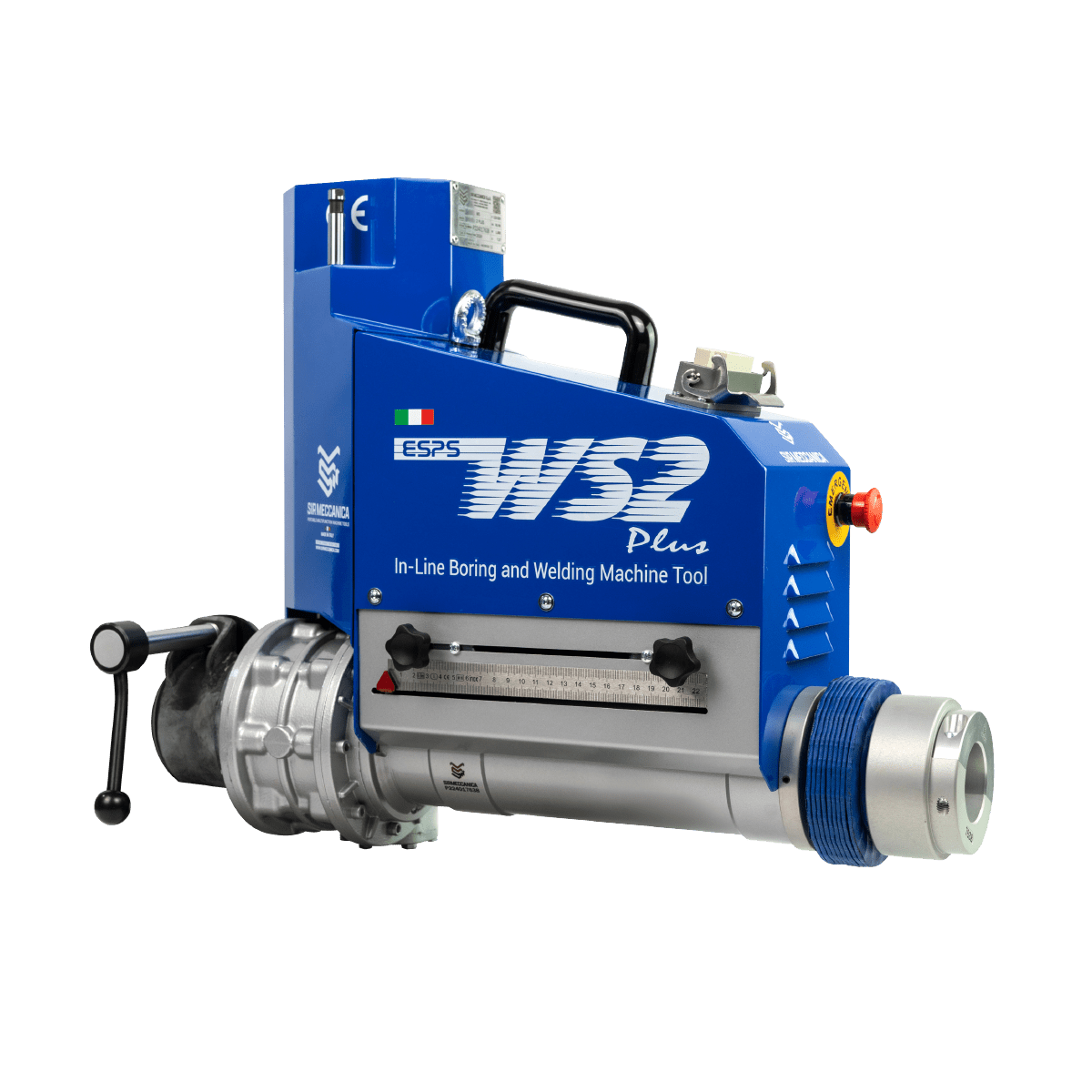

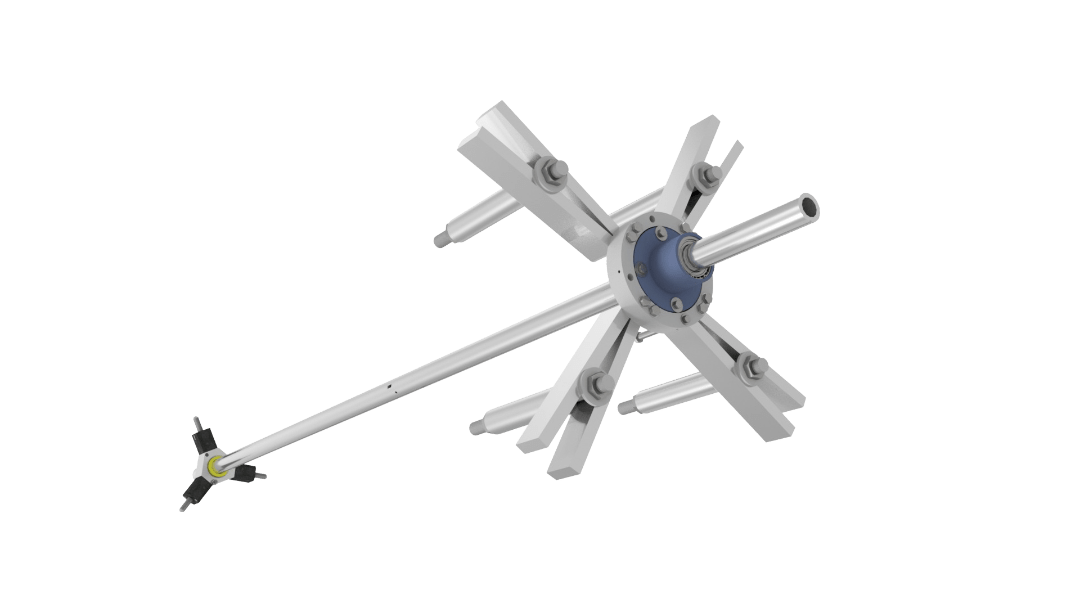

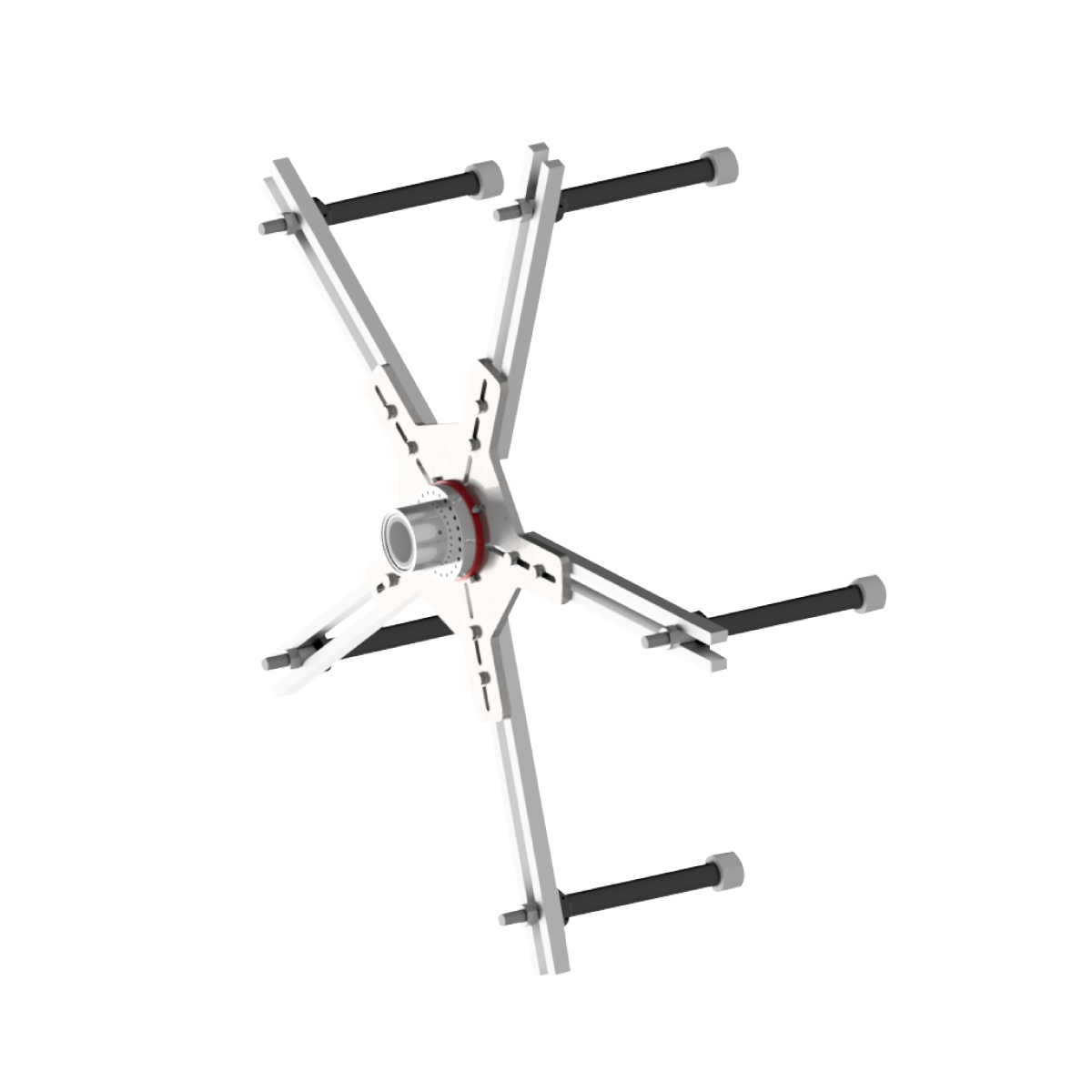

Серия Ws включает восемь моделей мобильных расточно-наплавочных комплексов. Каждый станок работает на определенном диапазоне диаметров и обеспечивает высокоточную обработку отверстий и соединений непосредственно на месте, без демонтажа оборудования. Это позволяет избежать простоев и транспортировки в специализированные мастерские.

Серии Подробнее

Станки Sir Meccanica отличаются высокой универсальностью и находят применение во всех отраслях промышленности. Они подходят для ремонта и обслуживания любых трубчатых деталей и могут работать в любом положении.

Благодаря мобильности, станки выполняют обработку непосредственно на объекте, что устраняет необходимость в демонтаже, транспортировке и снижает время простоя оборудования.

Станки Sir Meccanica быстро окупаются. Они просты в эксплуатации и не требуют привлечения к работе высококвалифицированных операторов. После установки на деталь, станок работает в полуавтоматическом режиме, сокращая время обработки до 95% по сравнению с традиционными способами ремонта.

Станки оснащены электронным пультом управления с дисплеем, позволяющим контролировать процесс обработки и быстро реагировать при необходимости.

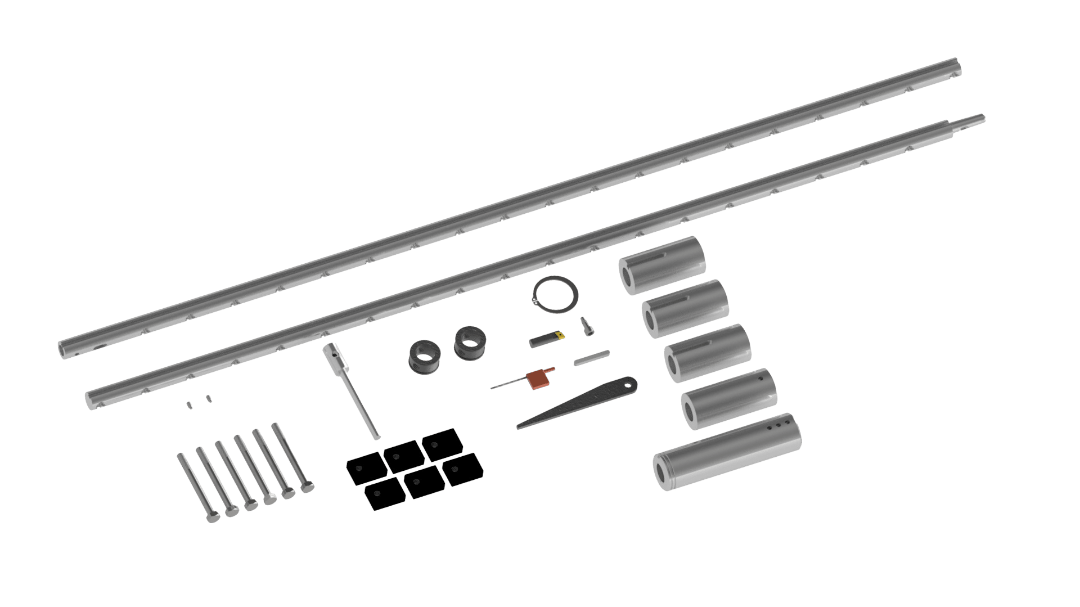

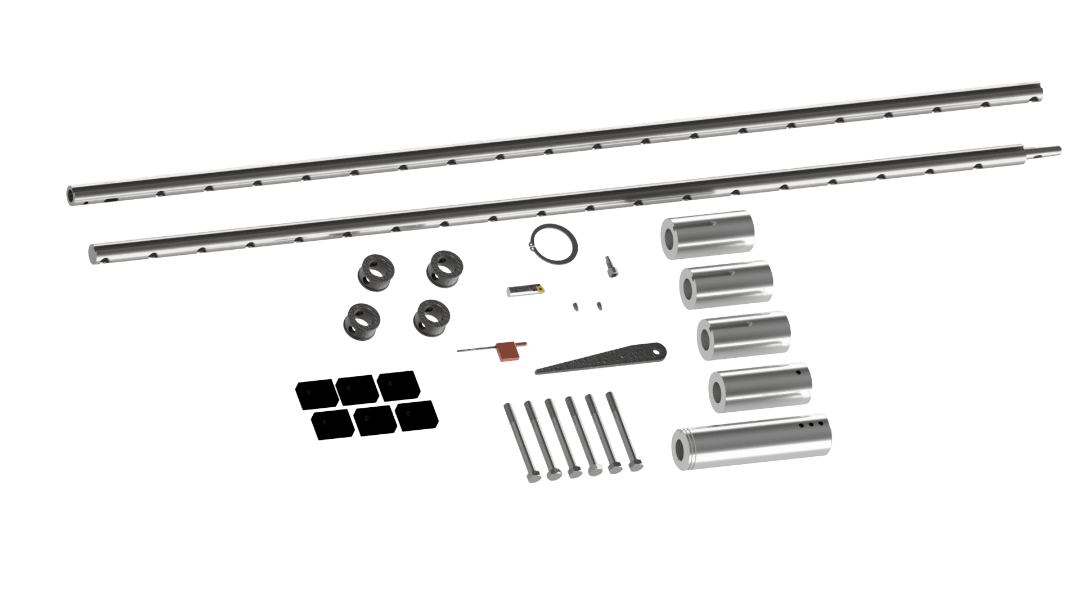

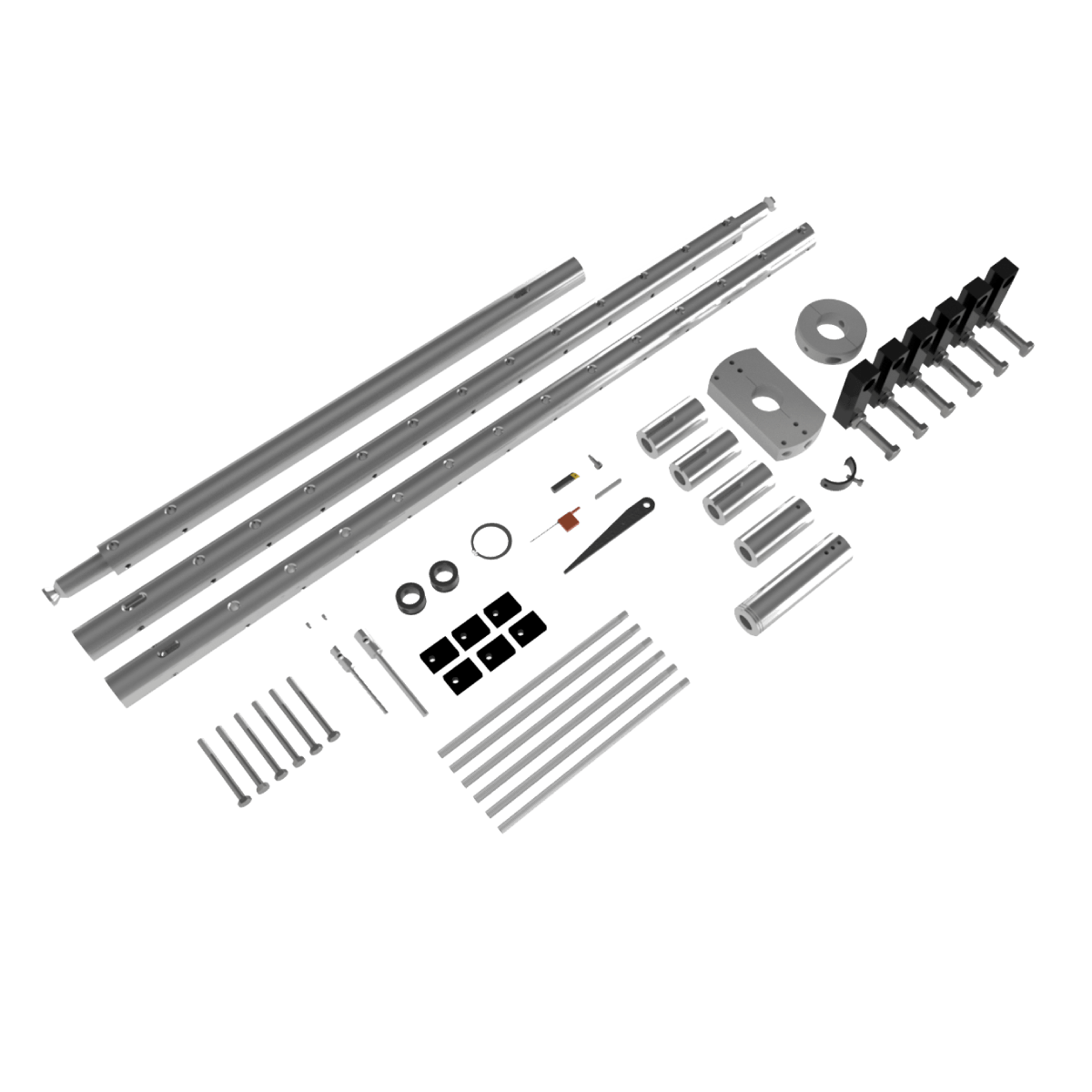

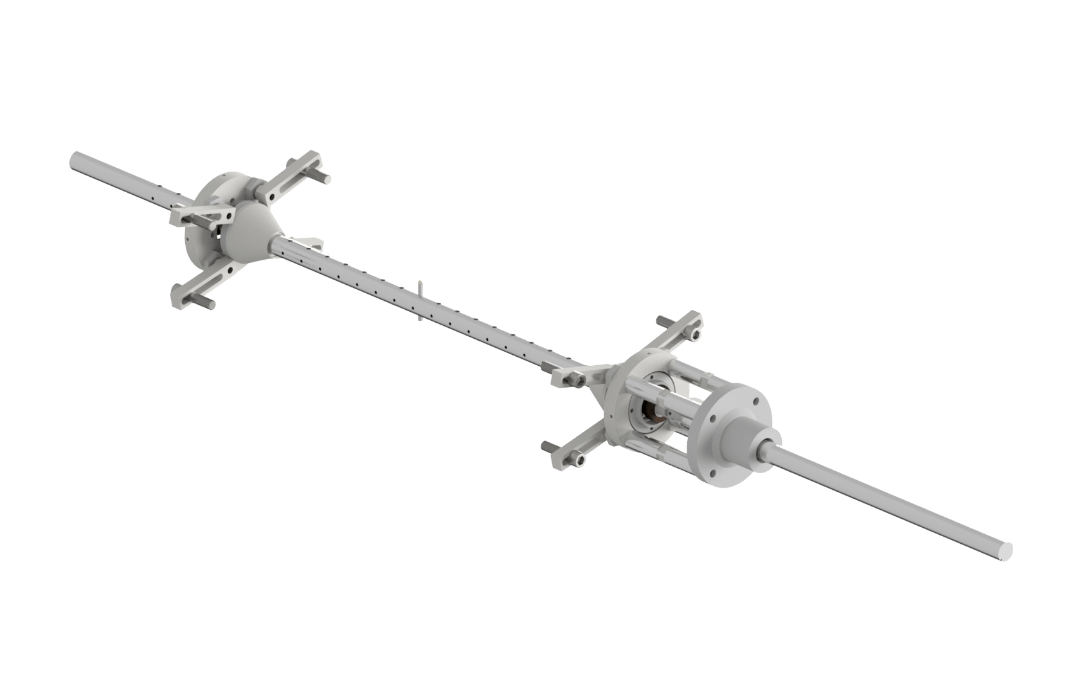

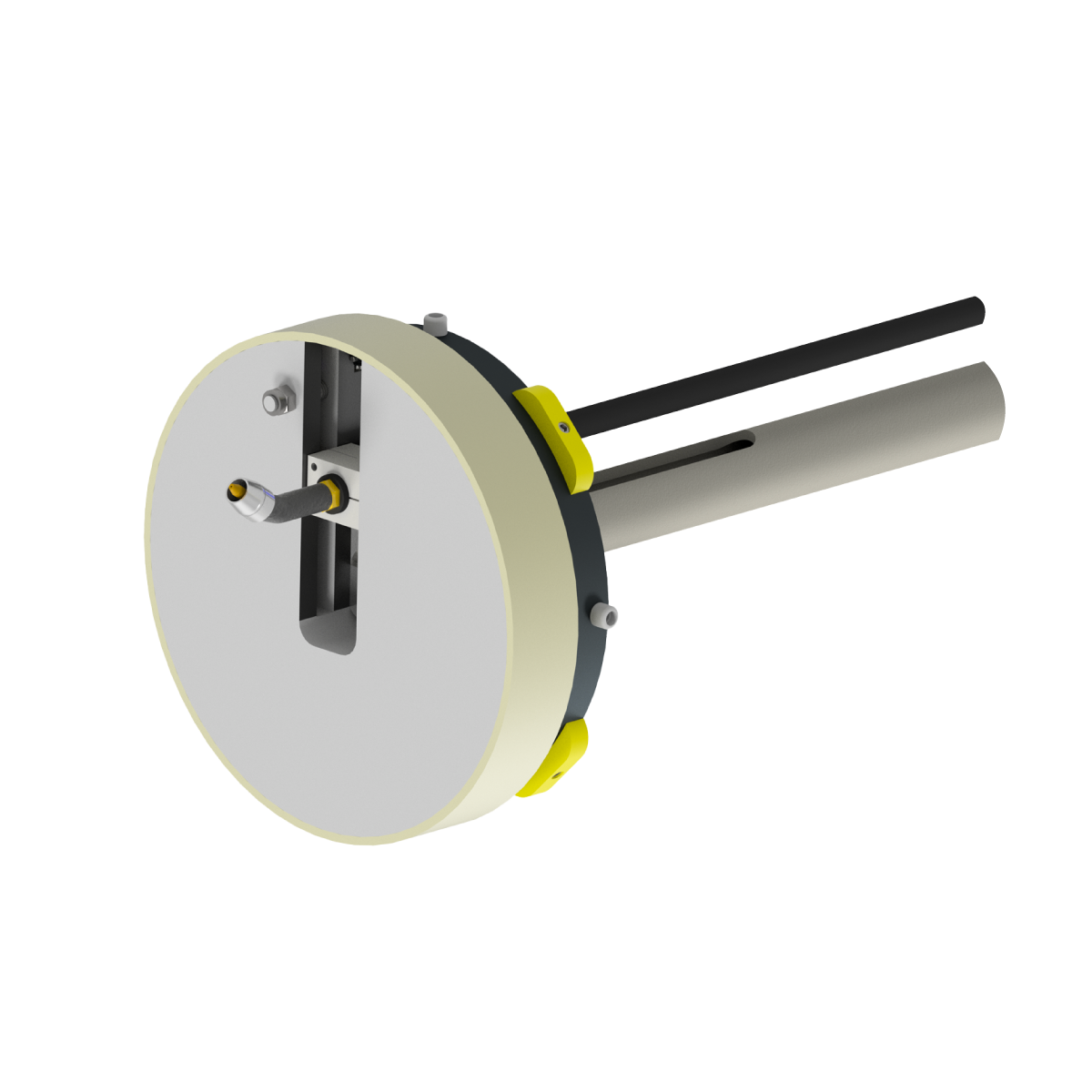

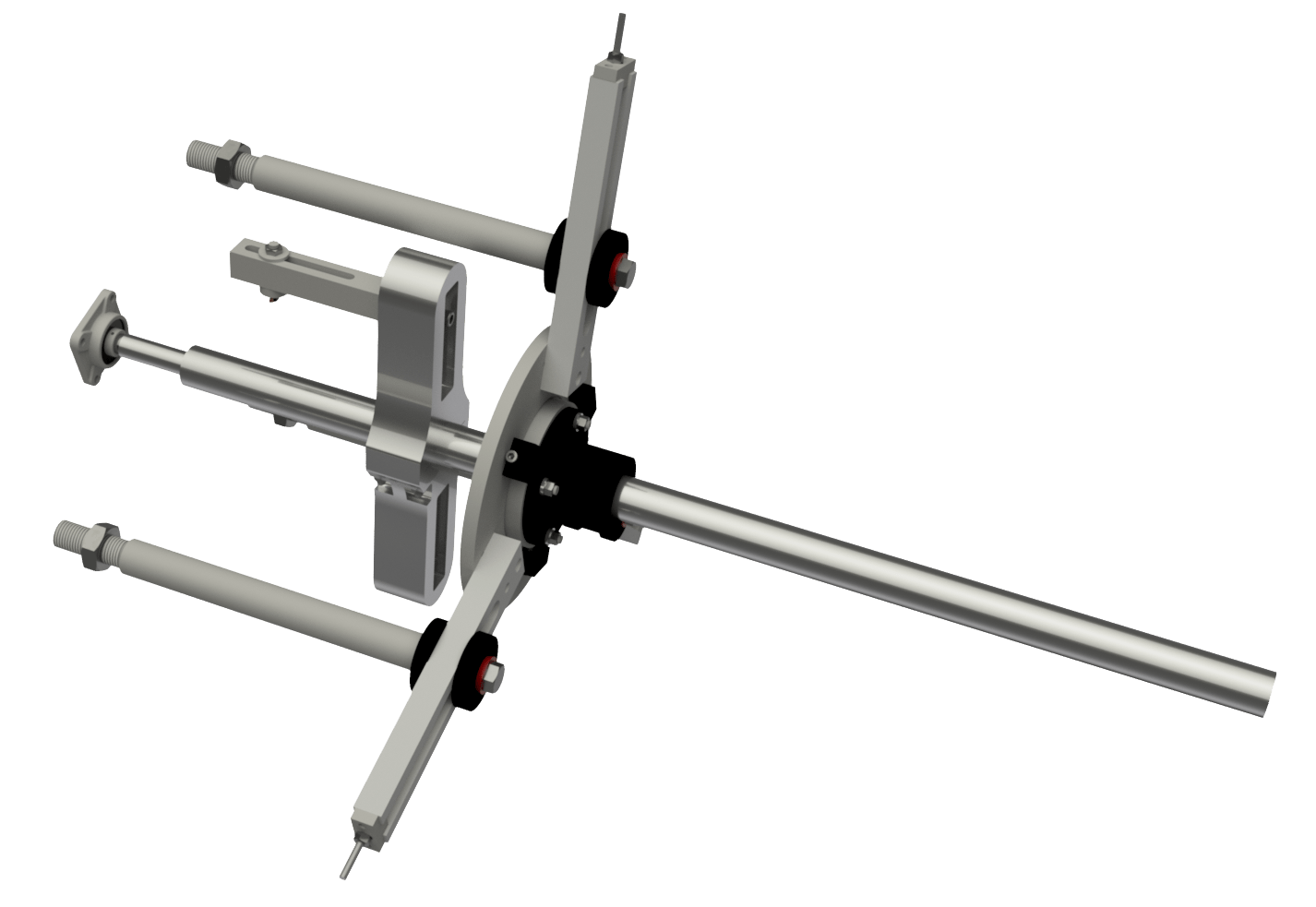

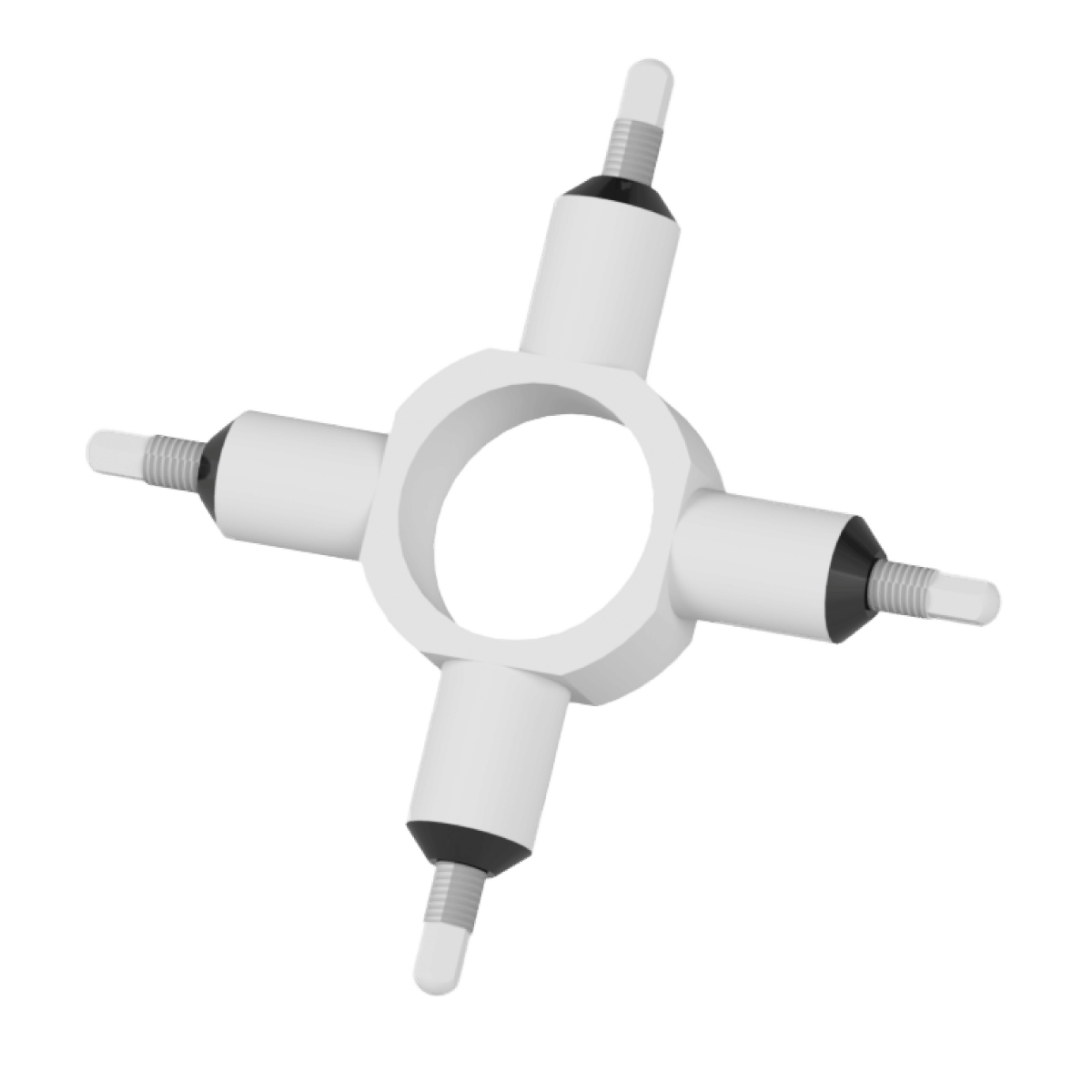

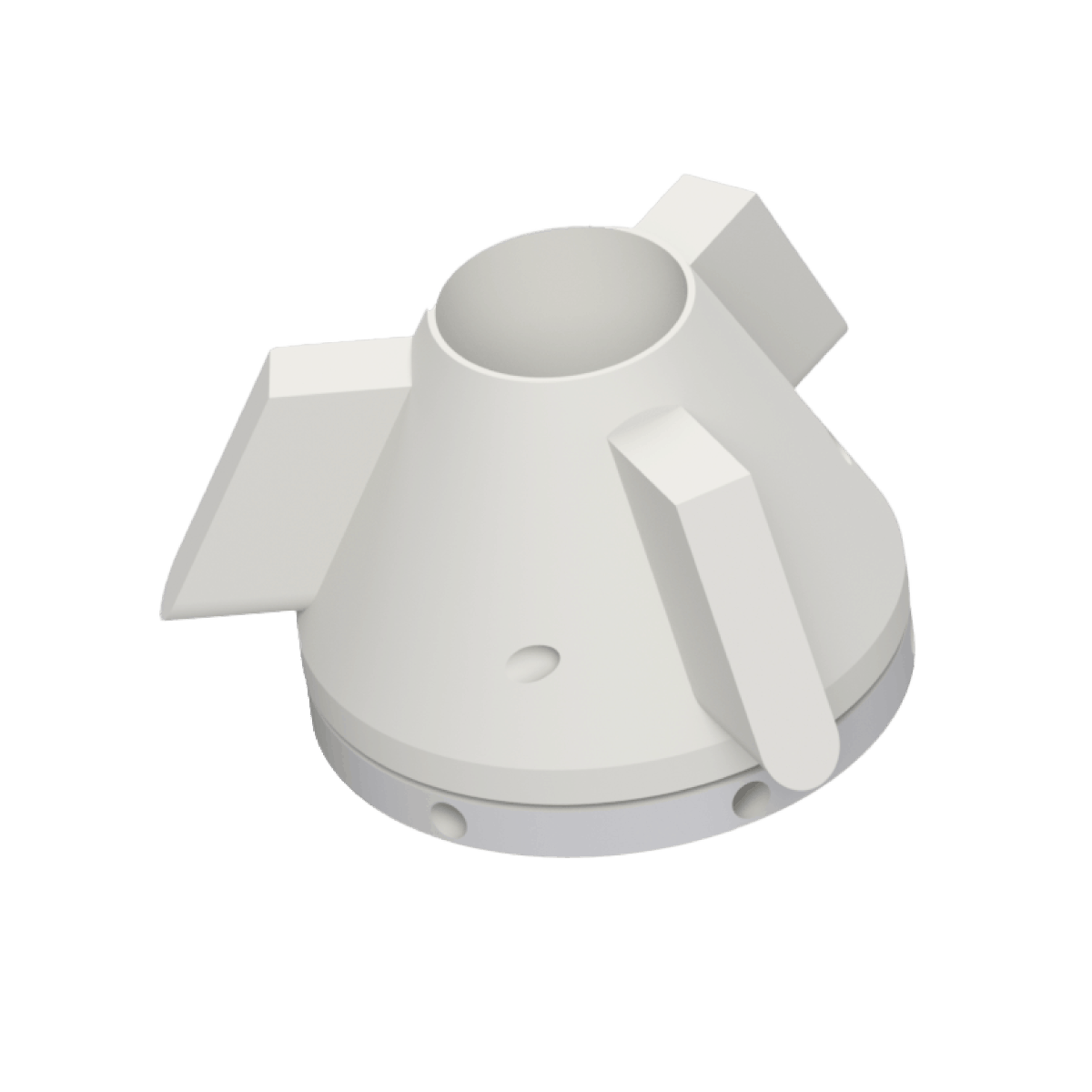

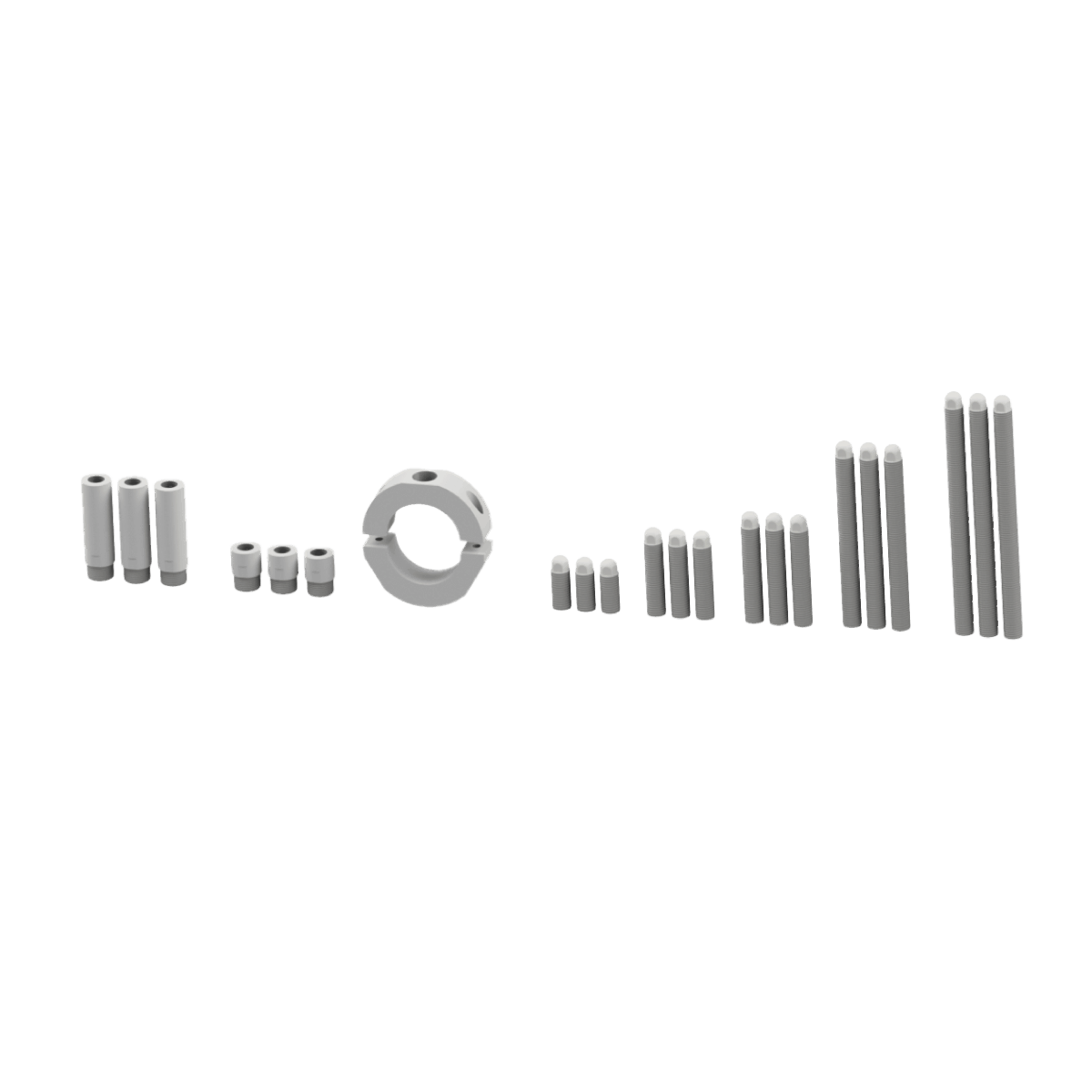

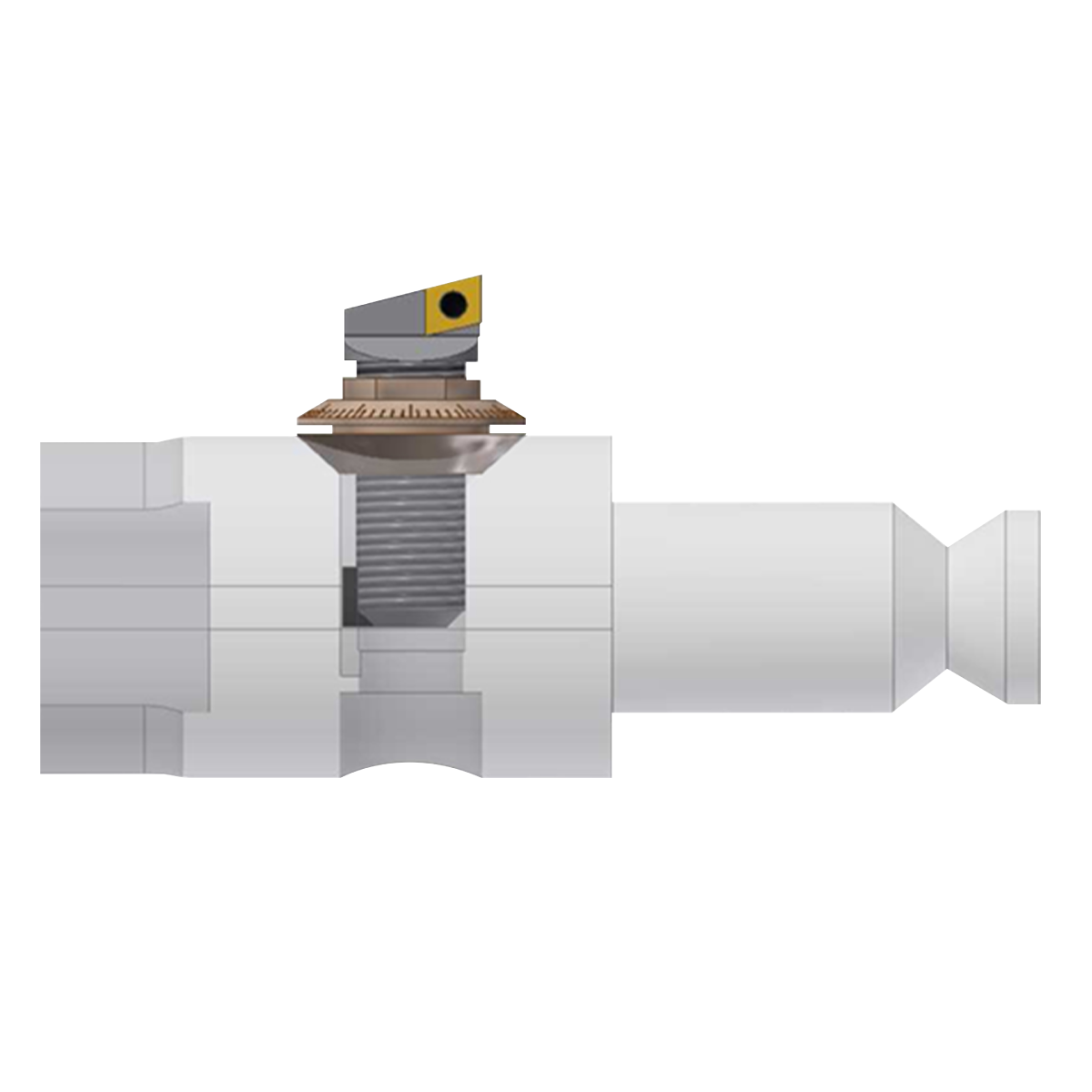

Сборные борштанги с коническим соединением — результат инженерных разработок Sir Meccanica.

Главная цель их разработки — создание высокоточных соединений, способных выдерживать значительные нагрузки.

Особое внимание уделено механизмам фиксации конических соединений, которые используются для сборки вращающихся и неподвижных компонентов, передающих большие крутящие моменты, а также элементов большой длины, работающих под высокими изгибающими и скручивающими нагрузками.

Модульная конструкция легко адаптируется как к коротким, так и к длинным зонам обработки. Она состоит из компонентов разной длины, которые можно быстро соединить для получения нужного размера. Эта универсальность делает систему Sir Meccanica по-настоящему уникальной.

Преимущества борштанг:

• быстрое соединение и разъединение;

• высокая точность соосности под нагрузкой;

• контроль уровня натяга на сопрягаемых поверхностях;

• стойкость к износу и нагрузкам;

• передача высоких крутящих моментов;

• повышенные коэффициенты безопасности;

• взаимозаменяемость компонентов.

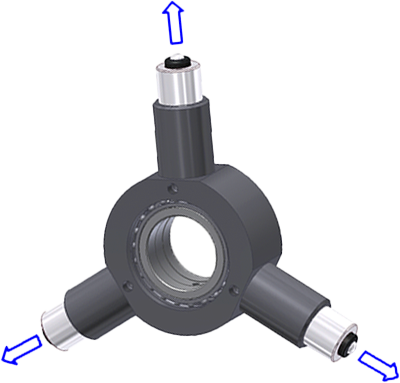

Качество обработки в прецизионном станке зависит от точности и равномерности движений. Sir Meccanica разработала современную панель управления для серии Ws, которая объединяет эффективные системы безопасности и управления.

Используемые компоненты, в сочетании с высококачественными производственными технологиями и инженерной проработкой конструкции, делают панель управления Sir Meccanica эталоном в своей категории.

Она отличается долговечностью, надёжностью и высокой эффективностью в работе, а также продуманной эргономикой, обеспечивающей удобство для оператора при длительной эксплуатации.

Основные функции панели:

• питание: 110–230 В~, 50/60 Гц;

• индикатор ST.P. — постоянный контроль усилия резания и нагрузки на двигатель вращения;

• система защиты от перегрузок и аварийной остановки;

• система ESPS® — электронное управление крутящими моментами двух двигателей с синхронизацией;

• звуковая и визуальная сигнализация с кодами ошибок для диагностики;

• дисплей скоростей подачи и вращения;

• кнопка быстрого перемещения борштанги;

• аварийная кнопка;

• Интуитивно понятная конструкция — позволяет эксплуатировать и обслуживать панель даже без специальных навыков.