W Smaller - Sir Meccanica

W Smaller

The Smallest One

Opis i aplikacje.

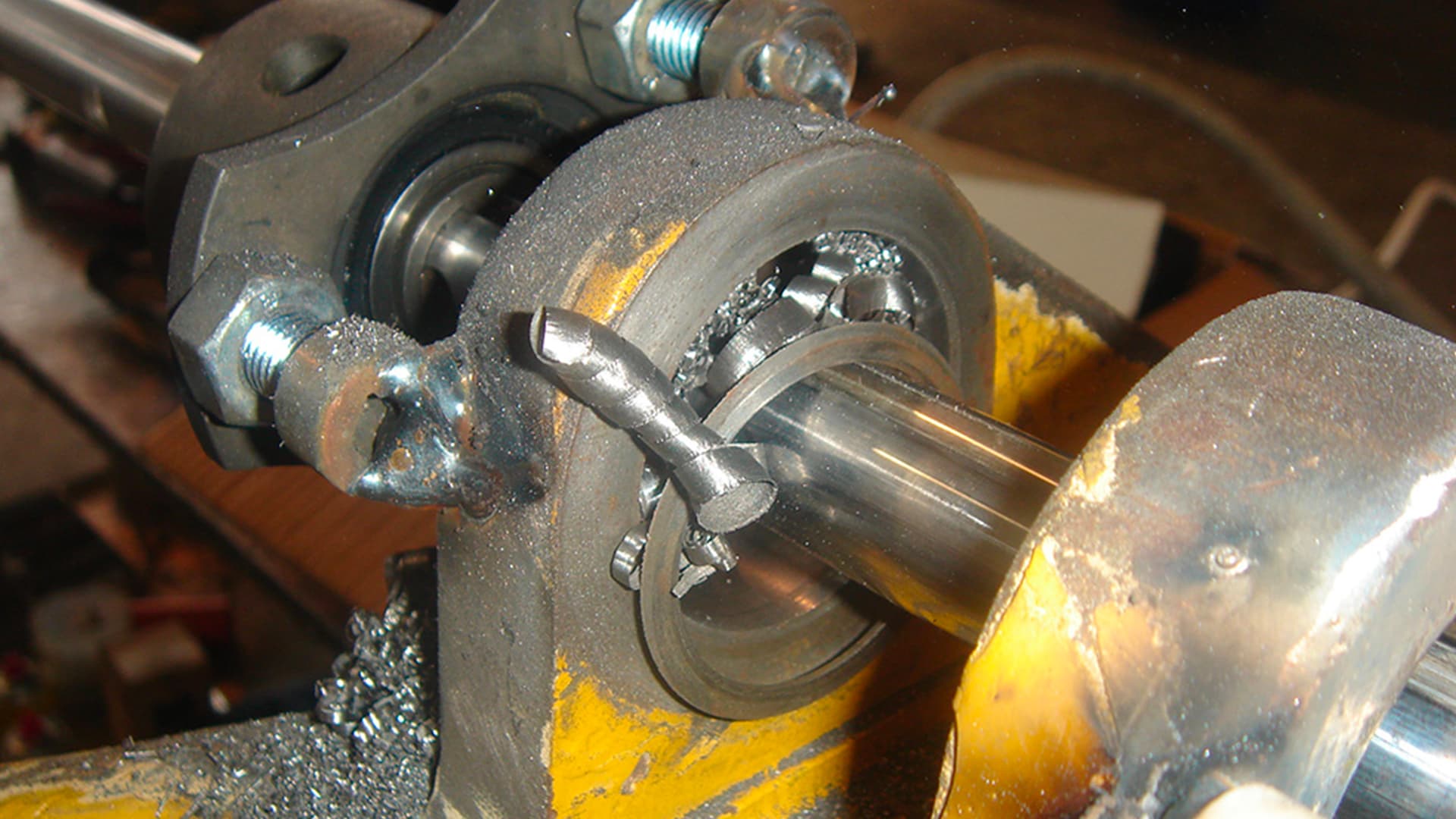

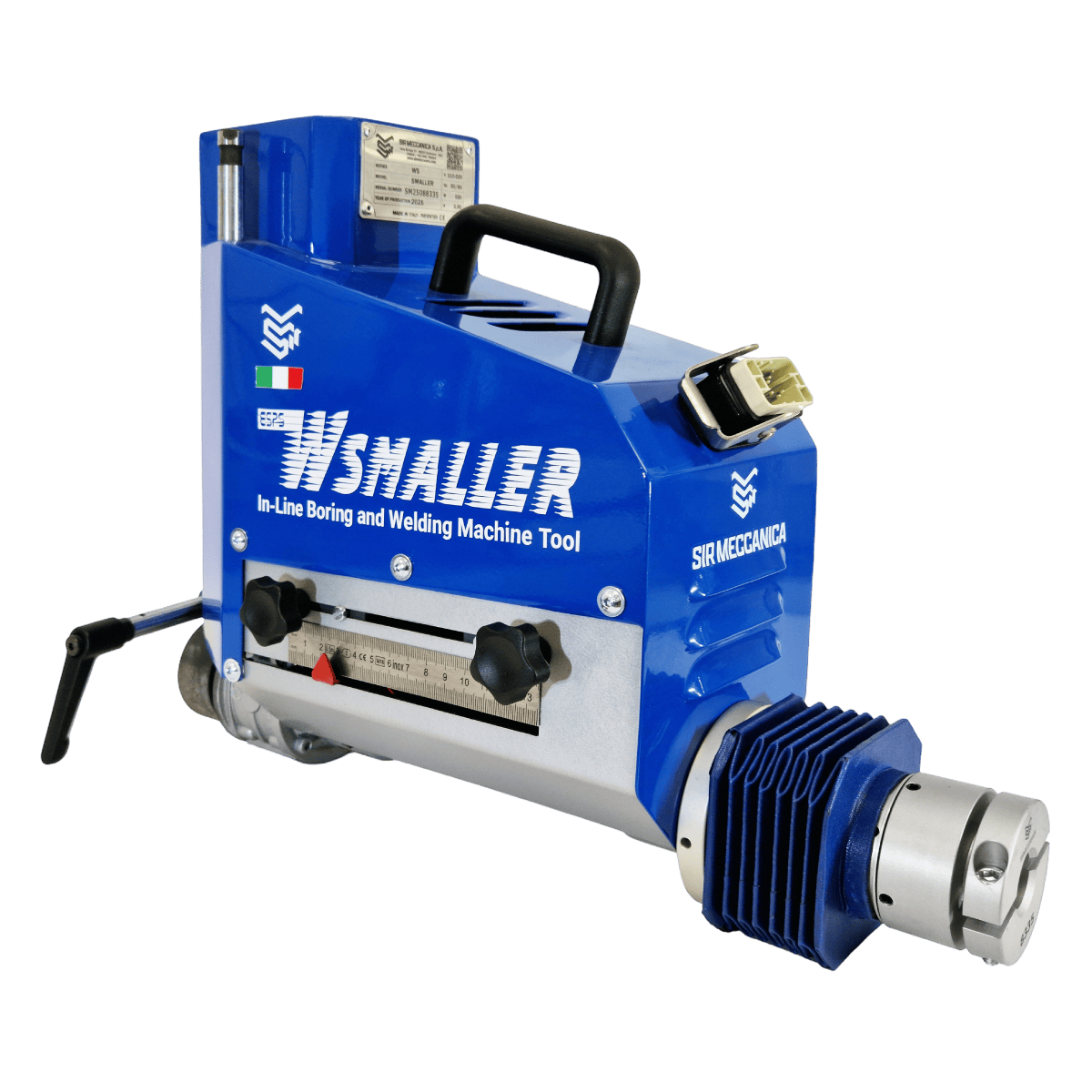

Capable of being positioned in the tightest spaces, small and easy to handle, the W smaller sums up the essence of the definition of “portable”. Designed to perform small-scale machining operations with practicality, extremely light and easy to move, this model is ideal for installations in places that are difficult to access and uncomfortable for the operator.

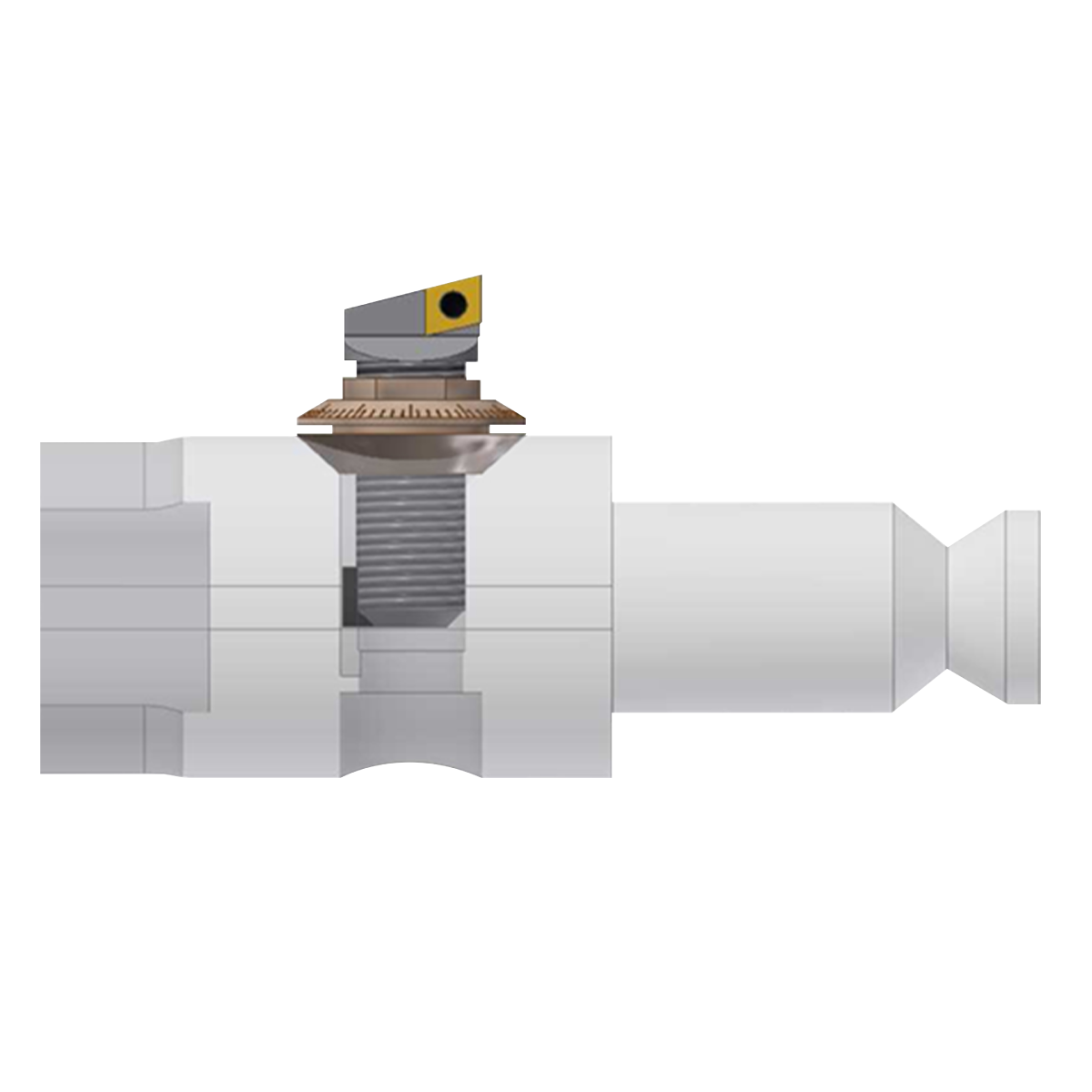

The axial feed is unlimited. A simple yet effective system allows to recover the 120 mm (4.72”) feed step, without changing the radial and axial position of the cutting tool, maintaining the set dimension and without leaving marks on the machined surface. For this purpose, the tool holder shafts have a patented conical connection which allows them to be connected to each other precisely, to cover long machining operations and/or to reach machining points far away from the machine body.

With the standard configuration the diameter of the W Smaller's shaft is Ø 20 mm and we supply three connectable boring shafts with conical coupling that will allow to cover a length of 2.500 mm (measuring 1.000 mm + 1.000 mm + 500 mm). Their chrome-plated surface makes them solid and wear-resistant, as well as it optimizes their sliding inside the machine and holders.

Also, the machine tool can be equipped with the KIT 2000 (facing head).

Drive unit weight: Kg. 12

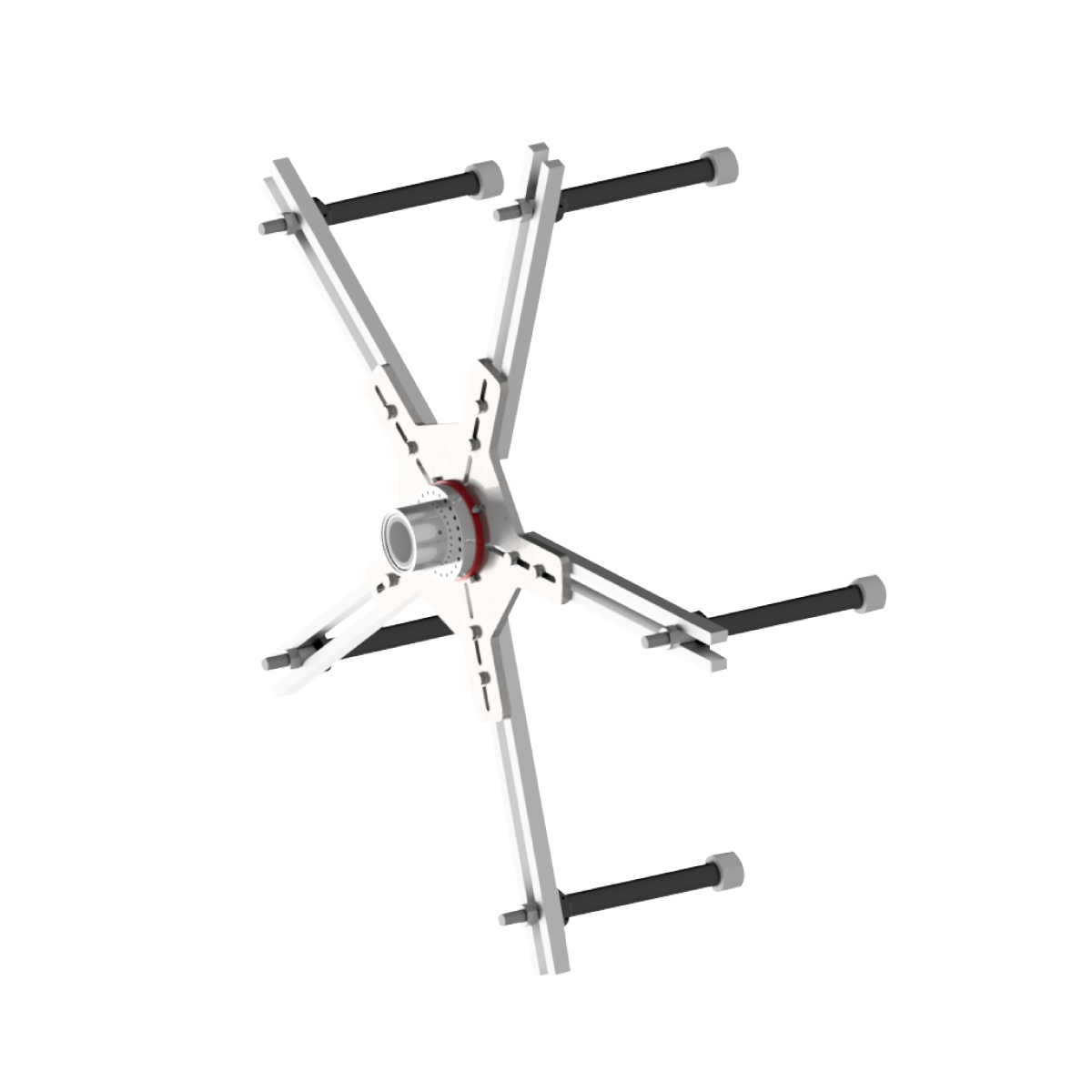

With maximum flexibility, by combining the two rotation and feed movements independently, the W smaller can perform:

Boring Diameters

Ø 22mm - Ø 70mm (0.87" - 2.75")

Overlay Welding Diameters

Ø 25mm - Ø 400mm (0.98"- 15.75”)

Szczegoly produktu

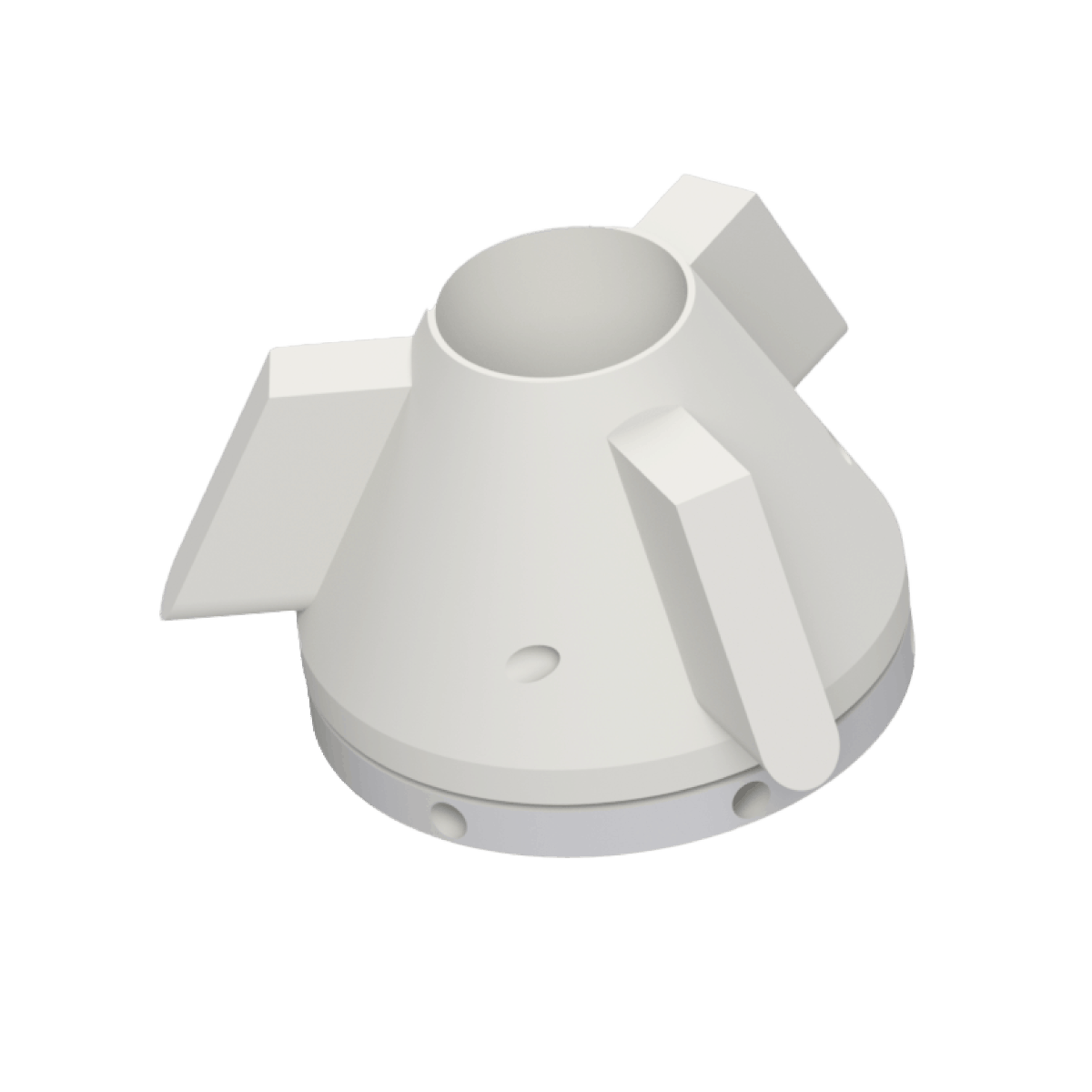

All the power needed to tackle any job in a single, strong, compact and easy-to-handle machine body, designed to absorb any stress in any working position. The ease of use and simple handling make these machines extremely versatile. Furthermore, this model can be equipped with optional KITS and a wide range of ACCESSORIES that expand its application.

The Ws series is characterized by a patented rotation transmission system featuring a worm gear - helical wheel type reductor with permanent lubrication. The careful selection of materials used and the production processes monitored by continuous quality controls ensure a strong and reliable transmission, which eliminates noise and vibrations during machining.

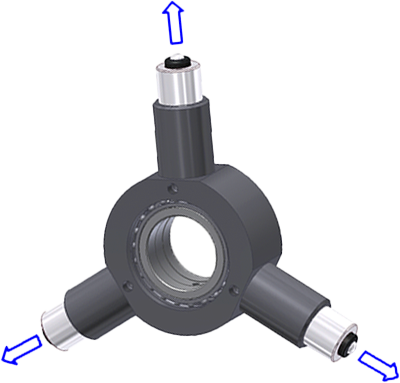

Fast and effective standard centering system. Specifically designed to be used in any working condition (misaligned, over-worn, oval-shaped holes, with non-uniform surfaces).

The microspand, supplied with the standard equipment, is an elastic expansion comparison tool, essential during the machine centering phase and during the measuring phases, between the various removal passes. It reduces time and errors by allowing to operate without the need to remove or move the tool-holder shaft.

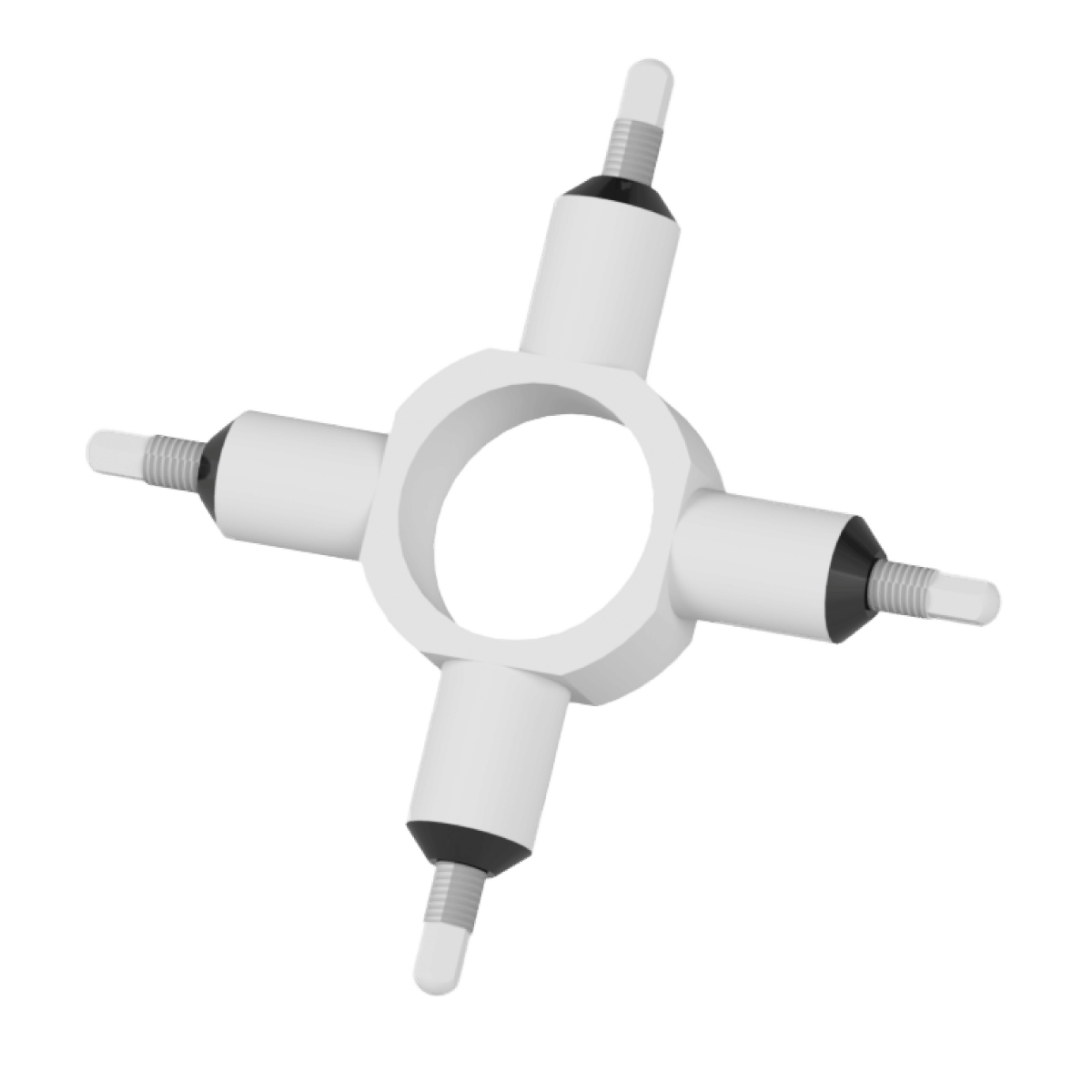

The CONNECTABLE SHAFTS WITH CONICAL COUPLING are the result of in-depth research conducted by Sir Meccanica.

The main purpose of our Research and Development work is to continue the commitment started years ago on precision couplings joints and their relative resistance to mechanical stresses

In particular, we conducted studies on the locking mechanisms of conical couplings, which are used to assemble rotating and stationery parts capable of transmitting high torsional moments, or to join thin axial components, extended in length and capable of resisting/withstanding large torsional torques and bending moments.

Perfectly adaptable to both minimal and infinite processing lengths, the patented system is composed of various modular components of different sizes that, assembled together, achieve the required dimension. In fact, the modularity of the system makes Sir Meccanica’s brand products and technologies even more unique. The key advantages of our shafts are:

- immediate coupling and uncoupling, for continuous assembly and disassembly;

- precision and quality in coaxial alignment under any stress conditions;

- excellent control over interference levels between coupled surfaces;

- resistance to wear and stress over time;

- high torque transfer capability;

- increased safety coefficients;

- interchangeability.

In a precision machine tool, the quality of the finishes is determined by a precise and continuous movement. By creating synergies between all the most efficient preventive and protective safety elements, Sir Meccanica has developed a cutting-edge control panel for the Ws series.

The components used, combined with high-quality production techniques and design expertise make Sir Meccanica’s control panel a benchmark for resistance, durability, reliability and great performance, even from an ergonomic point of view. Below are some of the key features of our control panels:

- power supply 110 - 230 V~ 50/60 Hz;

- ST.P. bar for continuous and instantaneous monitoring of the cutting force and of the workload of the rotation motor;

- safety system and emergency stop to preserve the integrity of the motor and the safety of the operator, in case of overload;

- ESPS® system (Electronic Synchronization Power System) for electronically managing the torque of the two motors with electromechanical synchronisation;

- acoustic warning and status display with coded signals, to detect and identify any faults during operation of the rotation and of the feed motor;

- display showing the feed and rotation speeds;

- button for rapid shaft translation;

- emergency button on the control panel, in compliance with European Community directives;

- user-friendly design, the control panel has been designed to facilitate any technical intervention, even by non-specialised personnel.

Photo Gallery